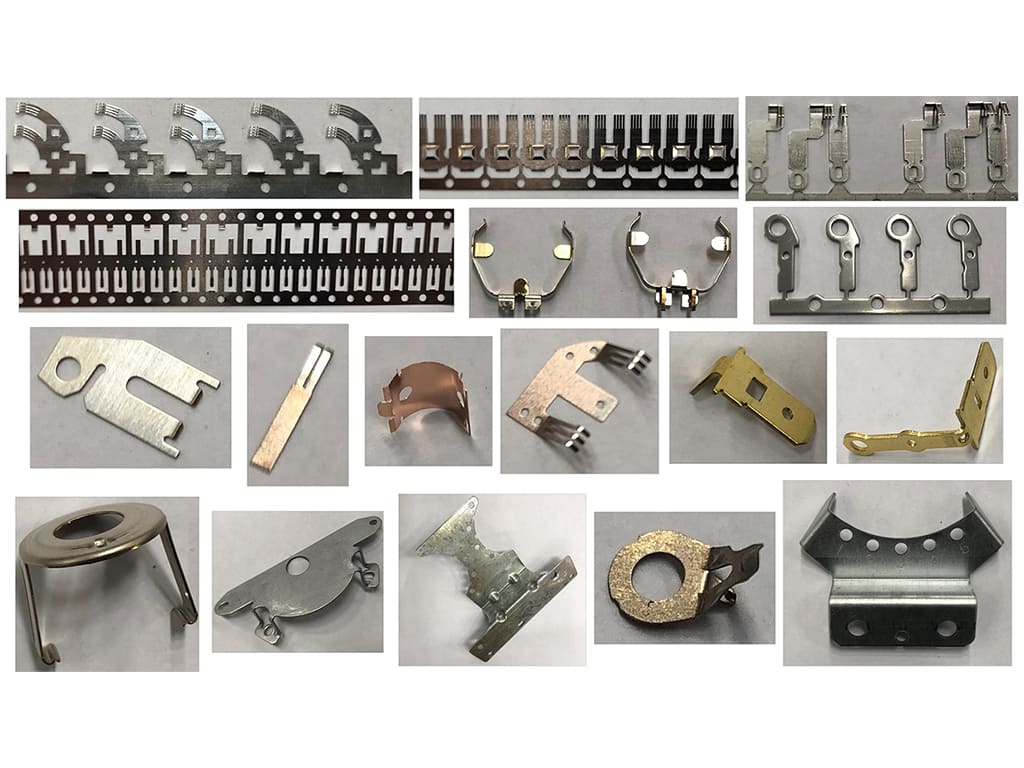

Metal machining / Plastic machining and its products.

Rapid Prototyping & Additive Manufacturing

Our process integration allows us to control a part design all the way through to production. In “Micro Labs”, we have a function inside of Micro dedicated to taking ideas that solve challenges and create newly improved designs. MicroLabs can also take an existing customer design and provide alternative iterations to enhance productivity and function. Rapid prototyping via additive manufacturing (3D printing) gives customers quick feedback loops and empowered iterative design, empowering them to move quickly towards production and improvement. Moving outside of the engineering office onto the factory floor, Micro give clients the intelligence they need to decide how best to manufacture a component. In some instances, it’s not an either/or scenario but a combined/collaborate approach that gets the best possible outcome at the most efficient outlay.

Microtechnologies